Ready-To-Install Assemblies & Branch Wire Systems (RTI)

Jobsite-ready electrical assemblies that streamline rough-in. Choose fast-shipping Stocked options or configure Made-to-Order (MTO) assemblies for your project.

TWO SIMPLE PATHS

Stocked or Made-To-Order — Your Call.

Pick from our stocked RTI catalog for immediate needs or configure job-specific assemblies with MTO.

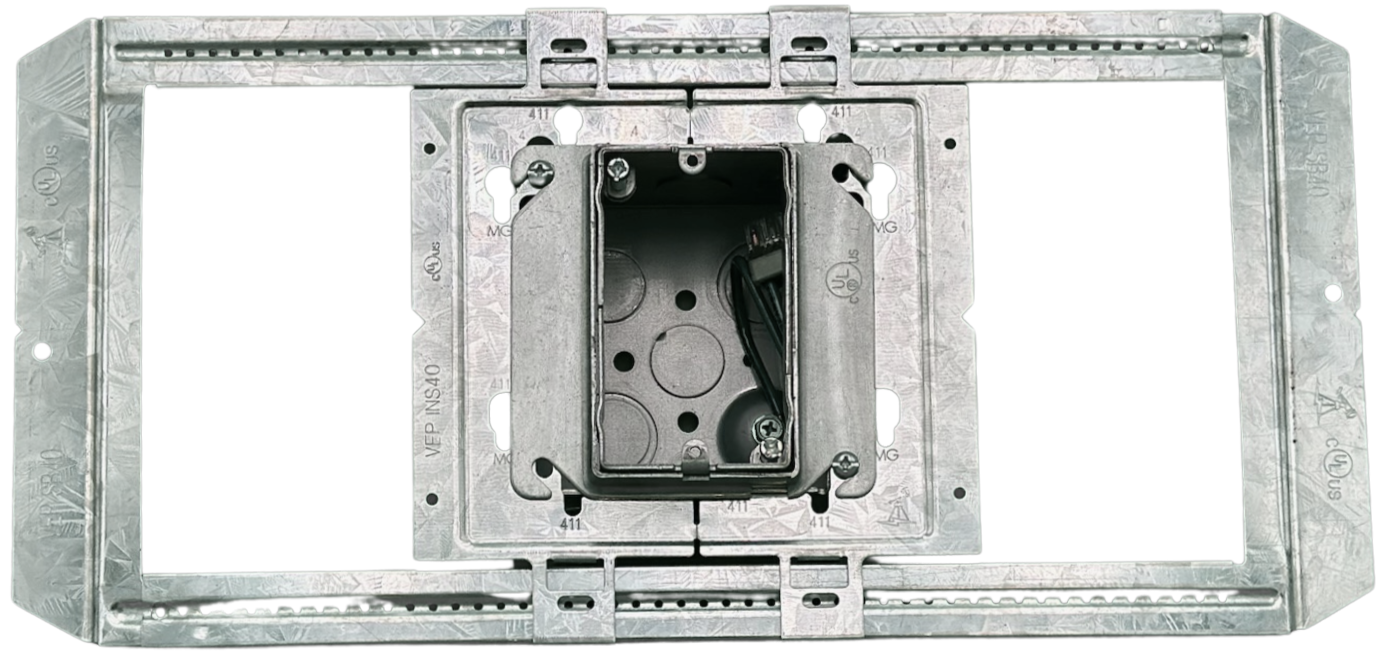

Assembly (A)

4D-62A-R2-SB1

4″ sq 2 -1/8″ Deep Box w 5/8″ Two Gang Adj. Ring w ground wire and w Slider Bracket

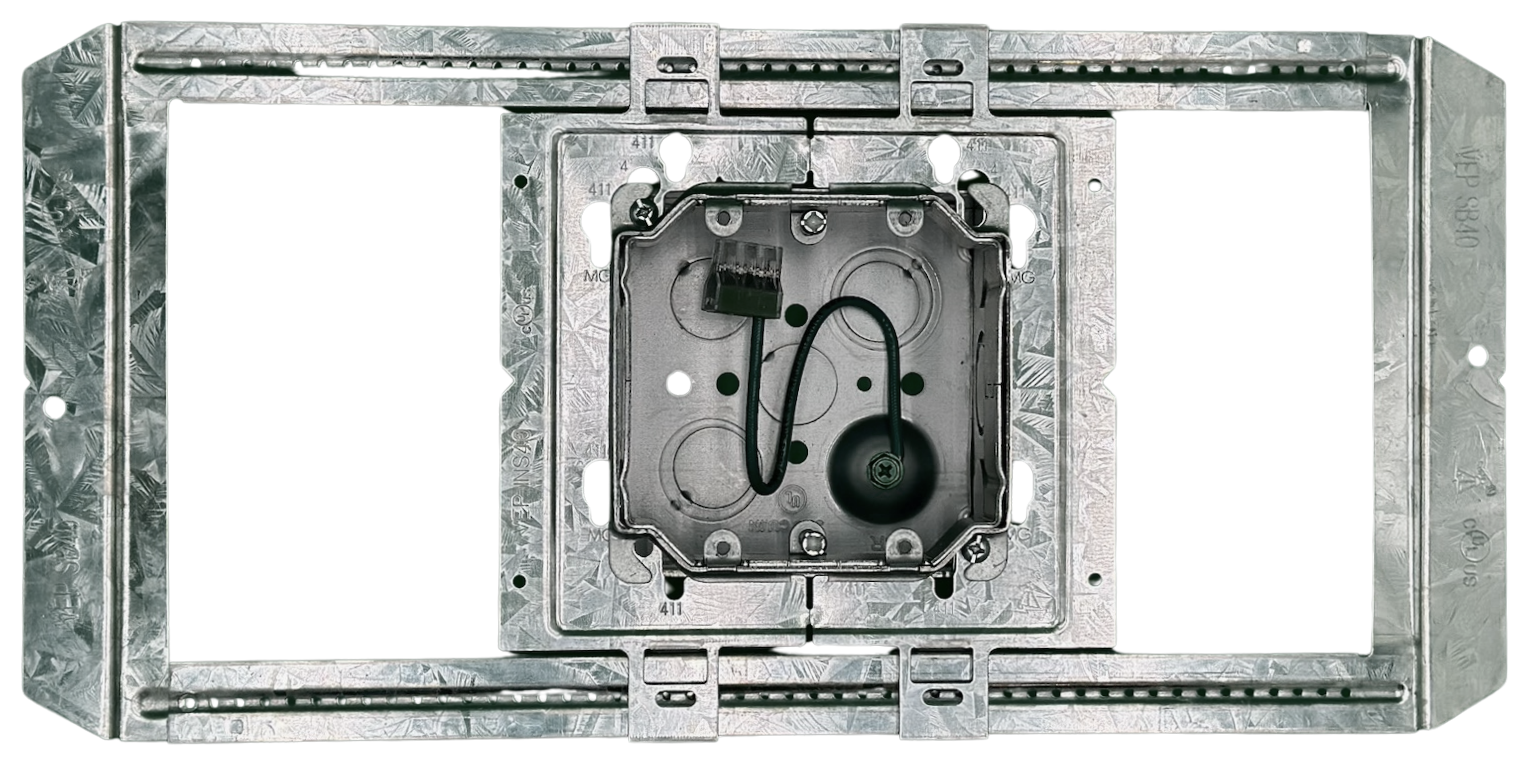

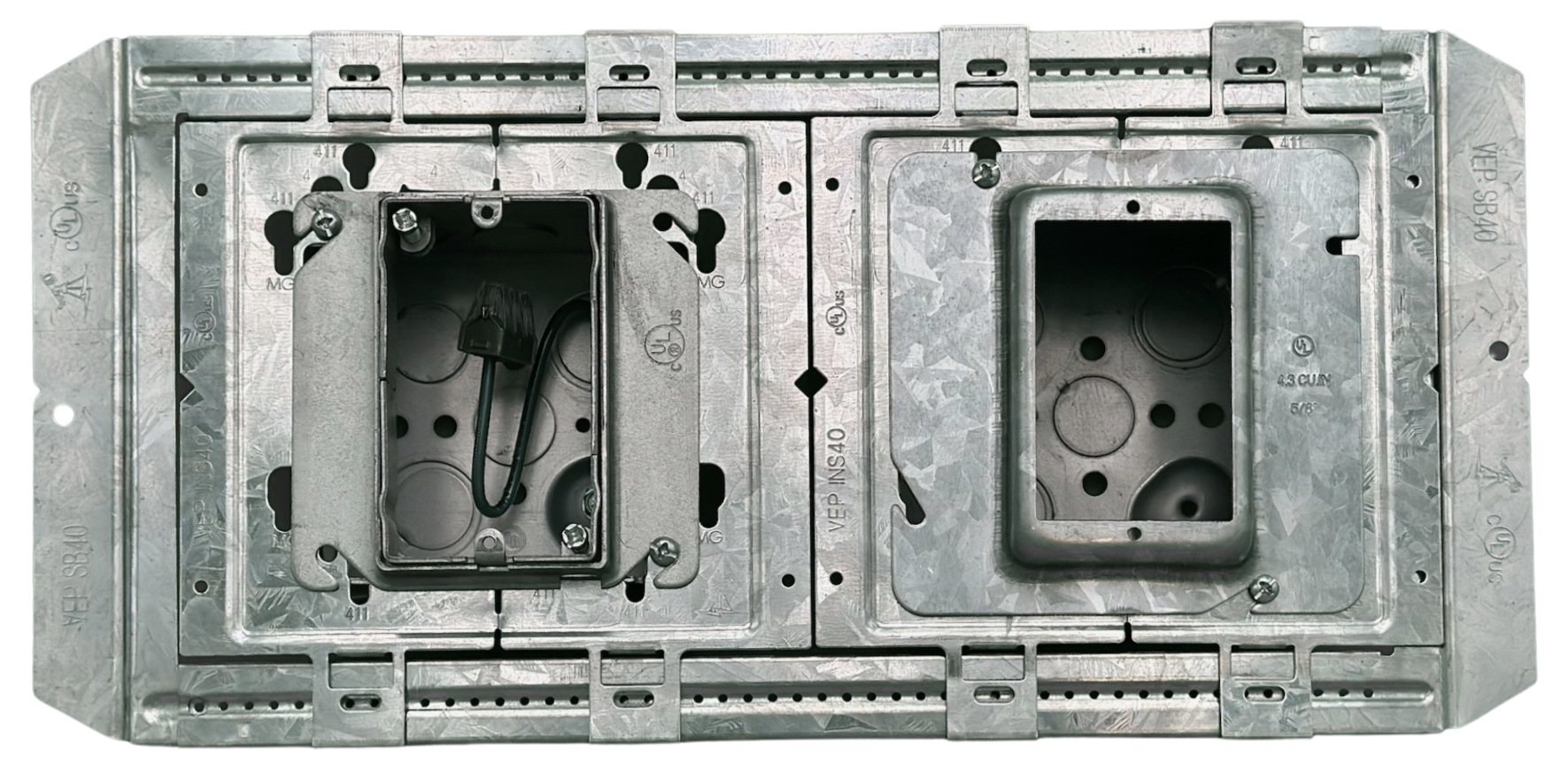

Assembly (B)

4D-62A-R1-CV-SB3-4D

4″ sq 2 -1/8″ Deep Box w 5/8″ Single Gang Adj Ring w ground wire on a Slider Bracket w 4″ 2 -1/8″ Deep Data Box w 5/8″ Single Gang Ring

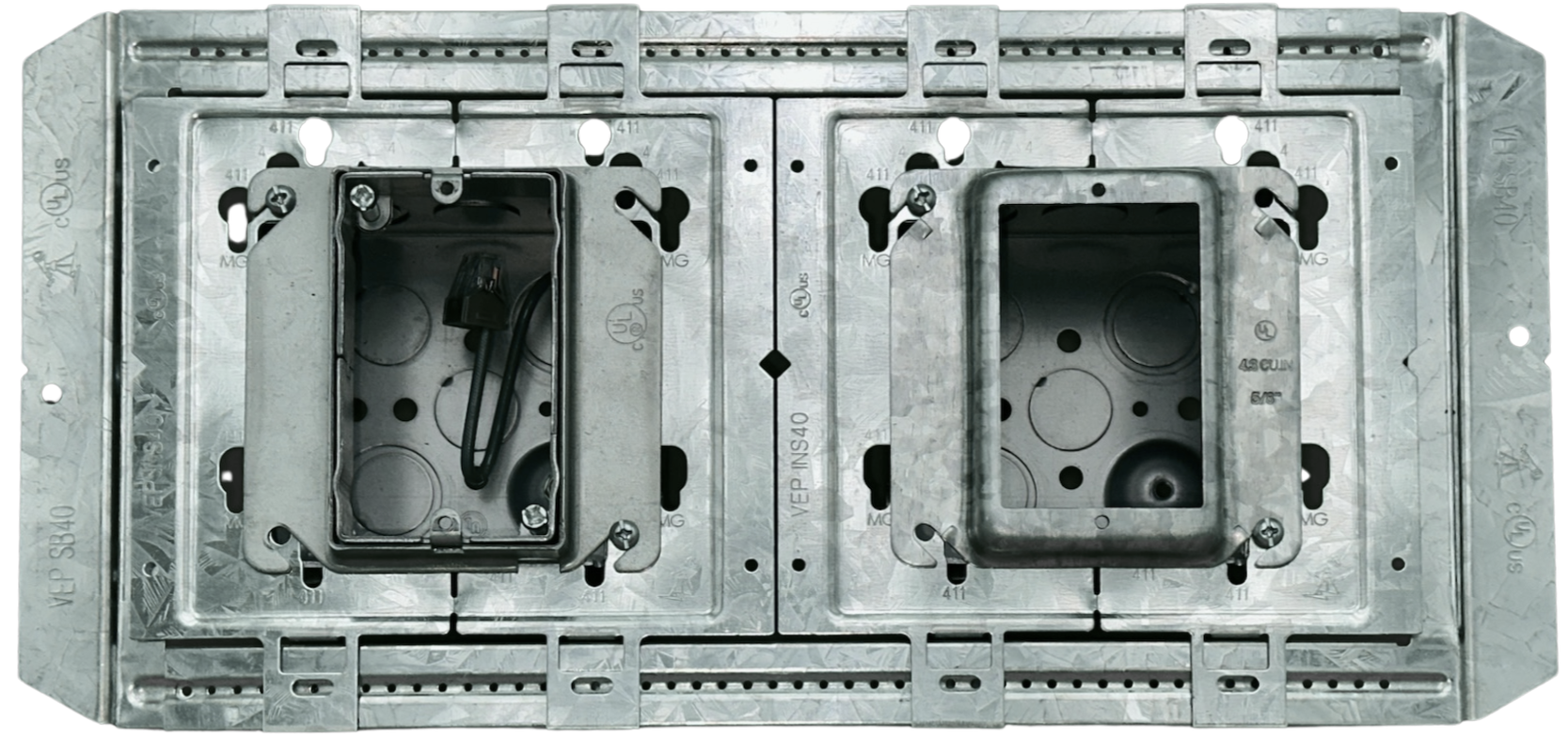

Assembly (C)

4D-62A-R1-SB1

4″ sq 2 -1/8″ Deep Box w 5/8″ Single Gang Adj. Ring w ground wire and w Slider Bracket

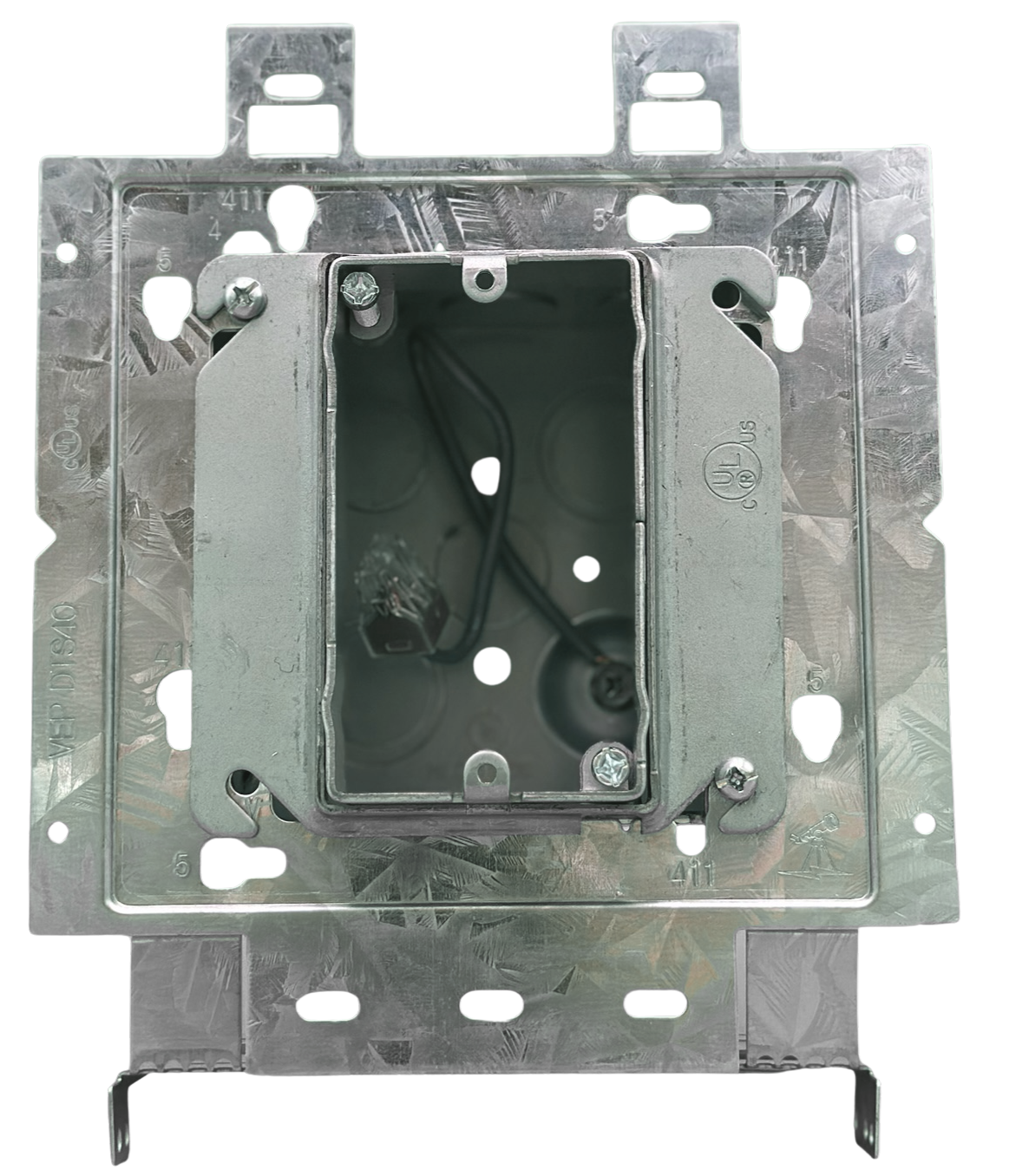

Assembly (D)

4D-62A-R1-DTS

4″ sq 2 -1/8″ Deep Box w 5/8″ Single Gang Adj. Ring w ground wire and w Direct to Stud Bracket

Assembly (E)

4D-62A-R1-CV-SB3-411D

4″ sq 2 -1/8″ Deep Box w 5/8″ Single Gang Adj. Ring w ground wire on a Slider Bracket w 4-11/16″ 2 -1/8″ Deep Data Box w 4-11/16″ 5/8″ Single Gang Ring.

NEXT STEP

Ready to Streamline Rough-In?

Send us your list of assemblies or request a quick quote.

WHY RTI

Built for Schedule Certainty, Consistency, and Cleaner Installs

RTI streamlines repetitive rough‑in work with standardized, inspector‑friendly assemblies built from UL‑listed components.

QUALITY & COMPLIANCE

Built from UL-Listed Components with Proven Assembly Methods.

Made-To-Order (MTO)

Start with a baseline family, then tell us how you want it built. We’ll return a quick quote and lead time.

CHOOSE THE RIGHT READY-TO-INSTALL APPROACH

Stock/MTO vs. Engineered Systems

| Feature | Stock & MTO Assemblies | Engineered Systems |

|---|---|---|

| Design | Customers specify assemblies or choose from stock assemblies. | VESI designs complete branch wire system. |

| Best for | Common, repeat rough-in work and fast returns. | Large, highly repetitive scopes (hospitality, Multi-Family housing, etc.). |

| Lead Time | Stock; quick ship; MTO: short; scheduled. | Project-dependent; includes engineering. |

| Customization | Select from defined options (length, rings, brackets, devices). | Fully engineered to drawings, project specs and customer preferences. |

| Field Efficiency & Predictability | Strong for targeted tasks. | Very strong across large repetitive scopes. |