Built Fast – Built Right – Built for You

Product Families Covered

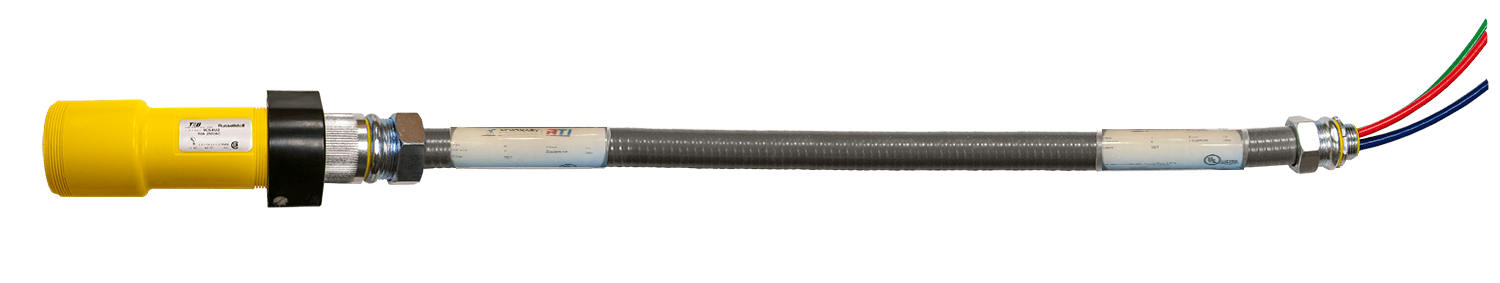

IEC 60309

Complete range of IEC 60309 pin and sleeve receptacle power whips.

NEMA

Complete range of locking and straight blade receptacle power whips.

Russel Stoll

Complete range of MaxGard & DuraGard receptacle power whips.

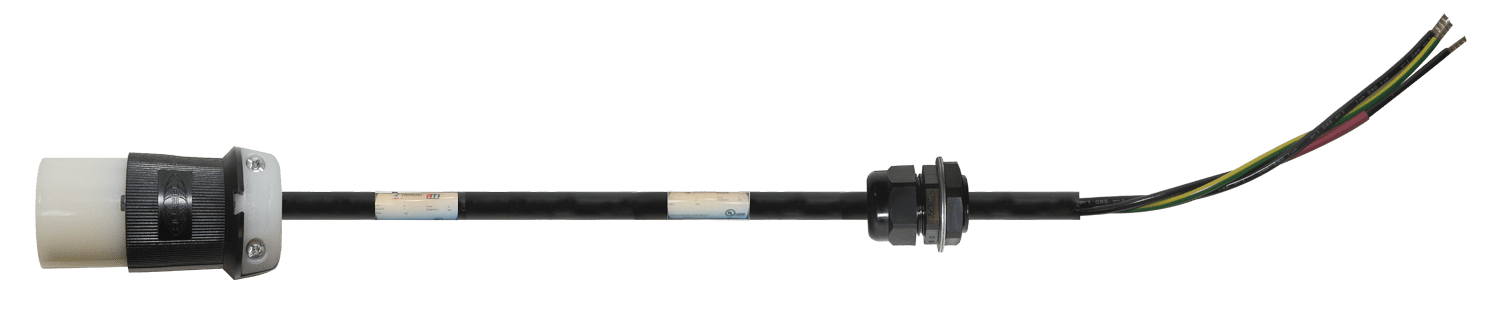

Tray-Cable

Complete range of IEC – NEMA – Russel Stoll connector and plug power whips.

SOOW-Cords

Complete range of IEC – NEMA – Russel Stoll connector and plug power whips.

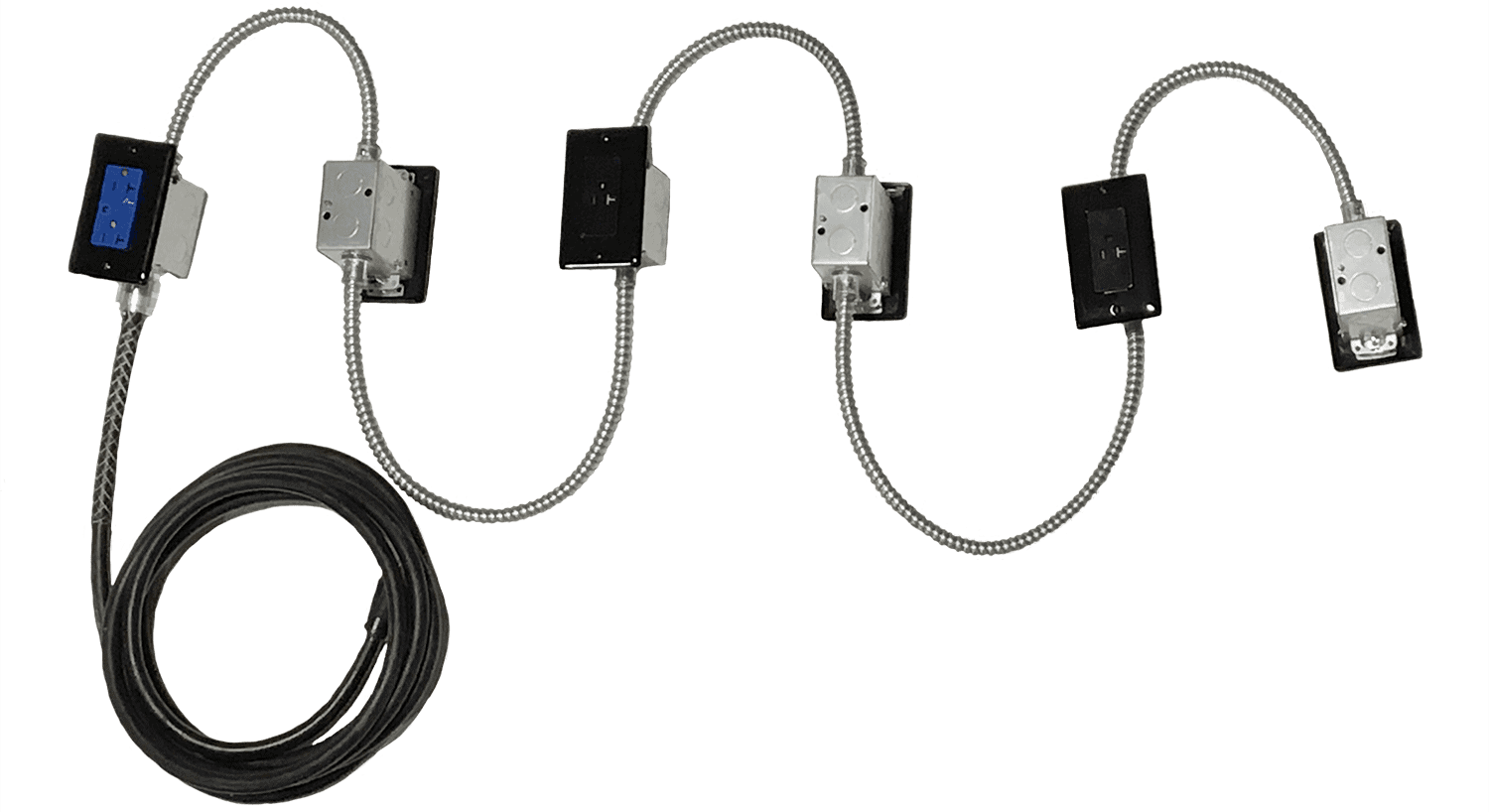

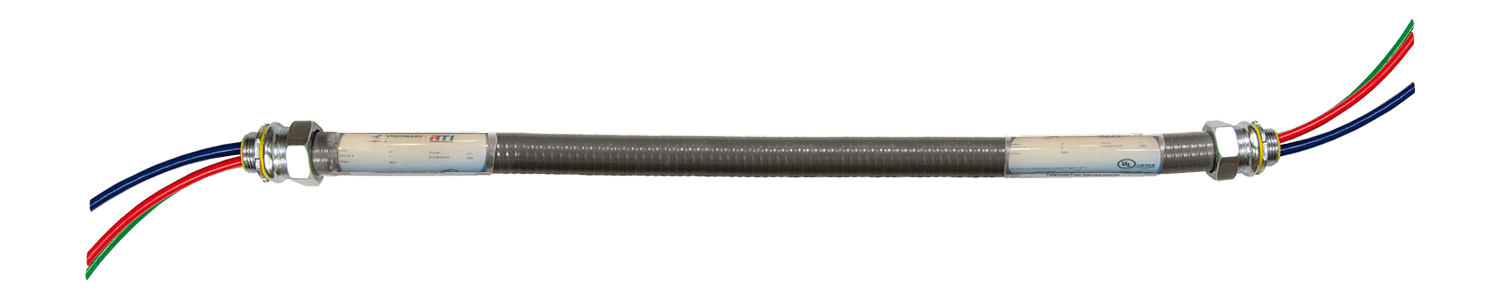

Field Whips

Manufactured with conduit and wire to the end user’s specification.

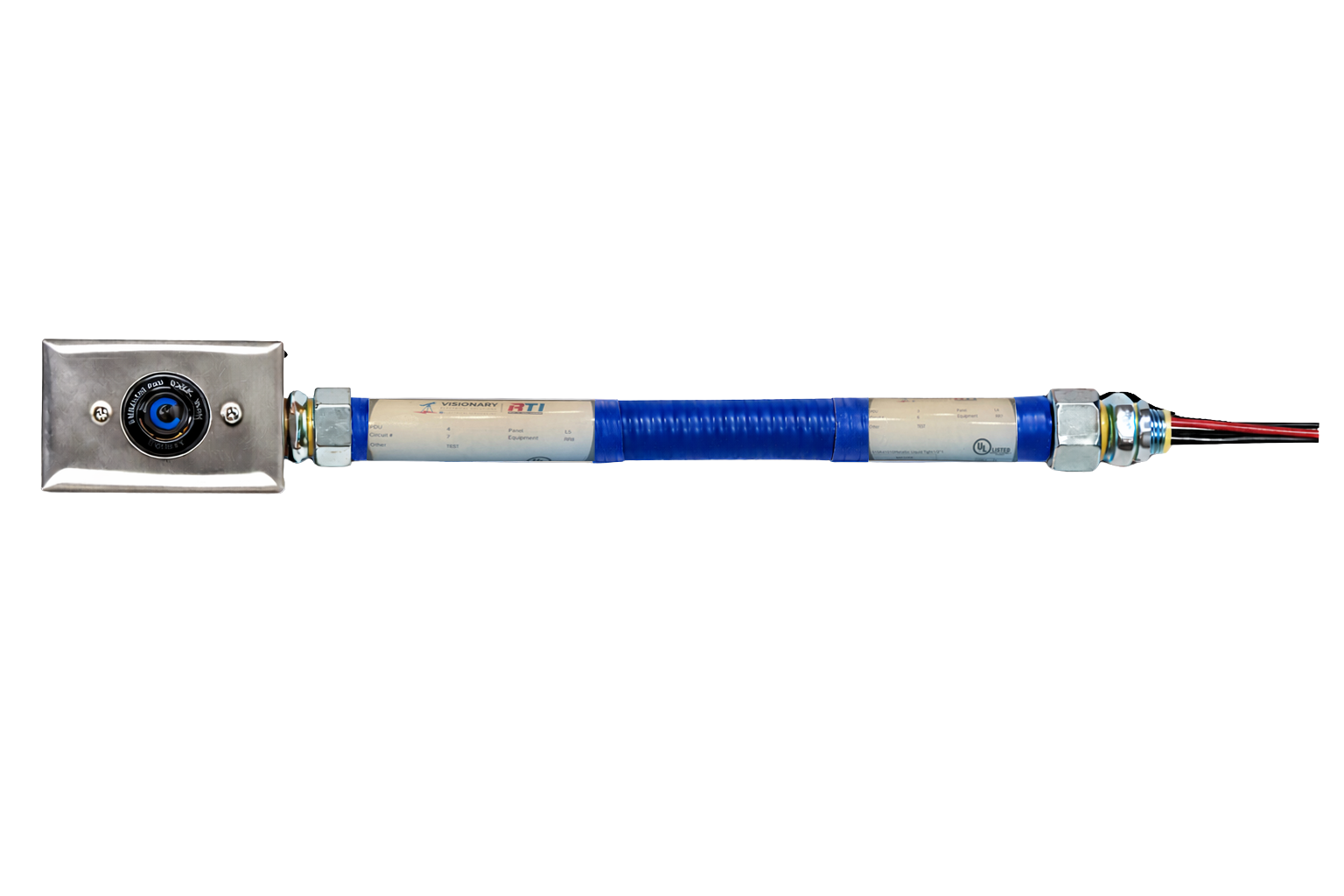

Data Center

Prefabricated Power Whips

Schedules

Built for Mission-Critical

Frequently Asked Questions

Do you provide documentation for commissioning?

What testing do you perform?