Visionary Electrical Solutions Fully Engineered Systems

VES designs and manufactures U.L.-listed, prefabricated branch wire systems engineered to project plans and specifications. These Engineered Systems reduce labor, improve quality, and accelerate schedules by shifting repetitive electrical work from the jobsite to a controlled manufacturing environment.

What is an Engineered System?

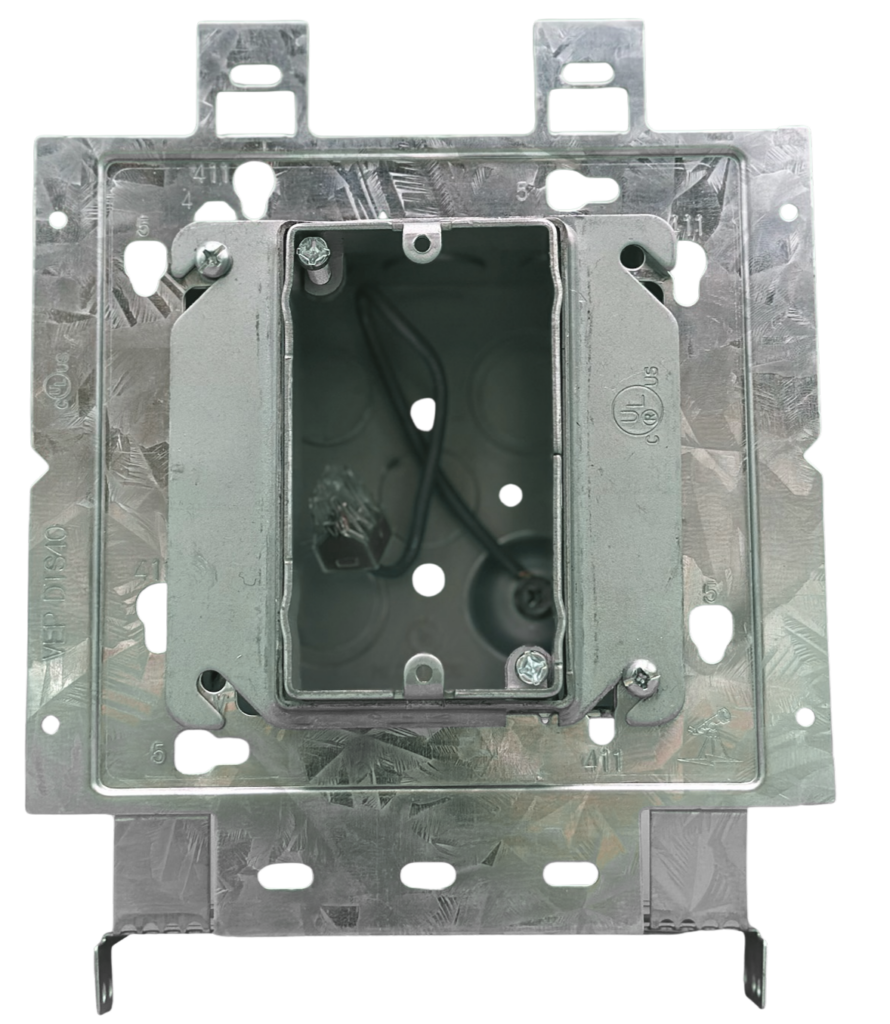

An Engineered System is a fully designed and prefabricated electrical branch wiring solution. Rather than assembling components in the field, electricians receive pre-built, labeled assemblies that are ready for installation. These systems are designed by professionals with decades of field experience, ensuring designs are practical, code-compliant, and efficient to install.

What’s Included in an Engineered System?

Each engineered system is tailored to the specific project and typically includes:

01.

Ready-To-Install assemblies

02.

Coordinated branch wiring layouts

03.

Labeled components by unit or area, and installation drawings

Assemblies are inspected for quality and correctness prior to shipment to ensure consistency and reliability.

Compatible Wiring Methods

Engineered Systems can be produced using MC Cable, NM Cable, or EMT. Regardless of the wiring method, the engineered approach remains the same, streamlining installation while maintaining flexibility based on project requirements.

Where Engineered Systems Are Used.

Engineered Systems are commonly utilized in apartments, condominiums, hotels, senior living facilities, medical office buildings, hospitals, schools, dormitories, sporting facilities, and tenant improvement projects.

Why Choose an Engineered System?

Engineered Systems help contractors overcome labor shortages, reduce jobsite congestion, improve installation consistency, and minimize material handling. By shifting labor off-site, contractors gain more predictable schedules, improved productivity, and increased profitability.

Installation Process

Systems are delivered with clear labeling and drawings. Installation typically includes layout using provided labels, mounting assemblies, routing cable per drawings, and completing final connections. This repeatable process improves speed and reduces errors.

Quality Control and Design Accuracy

Each system is engineered and reviewed by experienced electricians. Assemblies undergo visual inspection to ensure compliance with engineering standards, helping reduce rework and increase inspection confidence.

Change Management

VES supports project changes through integrated design and manufacturing processes that allow updates to be incorporated efficiently, even late in production.

Packaging and Delivery

Engineered Systems are palletized, shrink-wrapped, and labeled by unit or area for easy jobsite distribution. Deliveries are coordinated to align with project schedules and site restrictions.

Project Workflow

Projects typically progress from quoting and design to mock-up installation, production, delivery, and ongoing support throughout the project lifecycle.

OUR GUARANTEE

If after receiving the first shipment the Engineered System does not deliver the expected value, the remaining portion of the project may be canceled at no additional cost.

Let’s Get Started on Your Project!

Contact us today to discuss how we can enhance your electrical installations and streamline your projects.